Able to print at high speeds and maintain great quality.Very precise tolerances meaning flexible filaments can be printed easily.

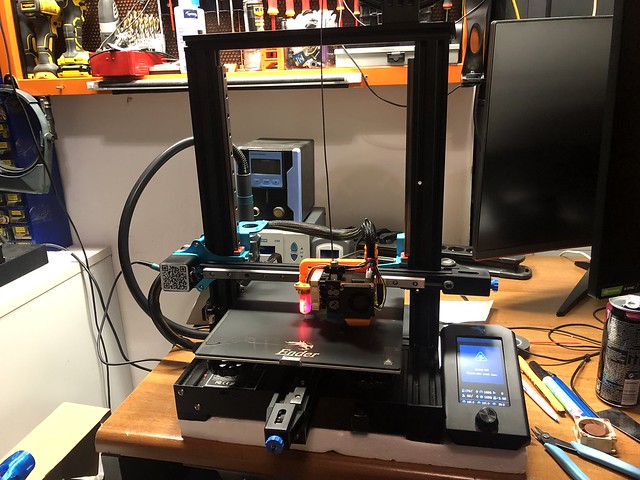

#Ender 3 v2 hemera upgrade

There are many upgrade guides out there for specific 3D printers so it shouldn’t be too difficult to get it done for your printer. So if you have an extrusion-based 3D printer, you should be able to upgrade it to the E3D Hemera. This combination of features gives you plenty peace of mind over the quality of your prints, and pushes you to aim higher in your printing abilities, rather than just printing basic items. It gives your 3D printer exceptional pushing force, serious control over starts and stops, better filament grip which reduces the presence of grinding and slipping, and decreased blobbing and stringing. The E3D Hemera delivers exceedingly precise results by featuring a dual-drive, very short filament path and a reinforced stainless steel drive train. It’s also obtainable as a Bowden extruder system so it fits most people’s needs. This allows 3D printer users to print flexible filaments with some of the industries best performance and accuracy, usually done at 50mm/s. The Hemera Extruder costs around ($130) from Amazon (or from the E3D website) for the Bowden & some extra for the Direct Drive version (around $150). What makes this extruder special is how it combines the market leading V6 hotend, with a newly developed filament drive mechanism which comes together to create an exceptionally responsive direct-drive extrusion system. It’s one of the best extrusion systems brought out on the market, so keep reading to see why.Ī lot of time was spent making sure this extruder is universal, compatible and easy to use for most people at a competitive price.īelow is a great video that summarizes the Hemera Extrusion System. Simply put, the E3D Hemera, is a state-of-the-art dual drive extrusion system which has put performance and user-friendliness at the forefront of its features. G1 X1.4 Y20 Z0.28 F1500.The time for performance is now, with the E3D Hemera Extruder (formerly known as the Hermes Extruder). Recv: echo: Acceleration (units/s2): P R T Recv: echo: Maximum Acceleration (units/s2): This is what I get for messing with perfection.Į3D Hemera Direct Drive kit with a V6 Hotendįilament: Sunlu 1.75 PLA Also Running Octoprint I had perfect prints before switching to this. I paid too much money to scrap this Hemera.

I don’t want to have to go back to the default hotend. I am looking for someone who can give me a hand in figuring out what I am doing wrong. I was using his firmware from the start as I liked the feature it came with and never had an issue with it.

I used his customer firmware maker to have the Hemera hotend changes put in. I am also running customer Marlin Firmware from the Australian guy that does nightly runs. As you can see in the picture the Temp tower sucks on all temps and the retention tower has no stringing on mostly all distances from 0.4mm to 1.4mm.

I tried to run through all the calibration steps on Teaching Tech and anything I print comes out crappy. I have been having a hell of a hard time with an E3D Hemera (/w V6 hotend) upgrade for my Ender 3 V2. Have to agree I like it more… Anyway let me get to my question. I come from the Resin community so not much along the lines of tinkering and upgrading your printer as you do with FDM. I’ve only had my Ender 3 v2 for about 9 months. Hello all, I am relatively new to FDM printing.

0 kommentar(er)

0 kommentar(er)